Project Description

In 2012 Keen Marine was asked to design and build items for the Subglacial Lake Ellsworth project lead by the British Antarctic Survey and undertaken by a consortium of Universities and research institutions. Now I can begin to reveal some details of these works with the acceptance for publication of the first paper to arise from this project.

The Lake Ellsworth project was an initiative seeking to drill down to, and sample, the waters and sediment of the subglacial lake, Lake Ellsworth, deep beneath the Pine Island Glacier in the Western Antarctic. The ice thickness over Lake Ellsworth is around 3000m.

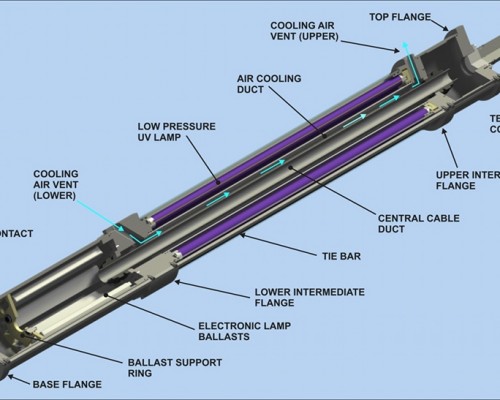

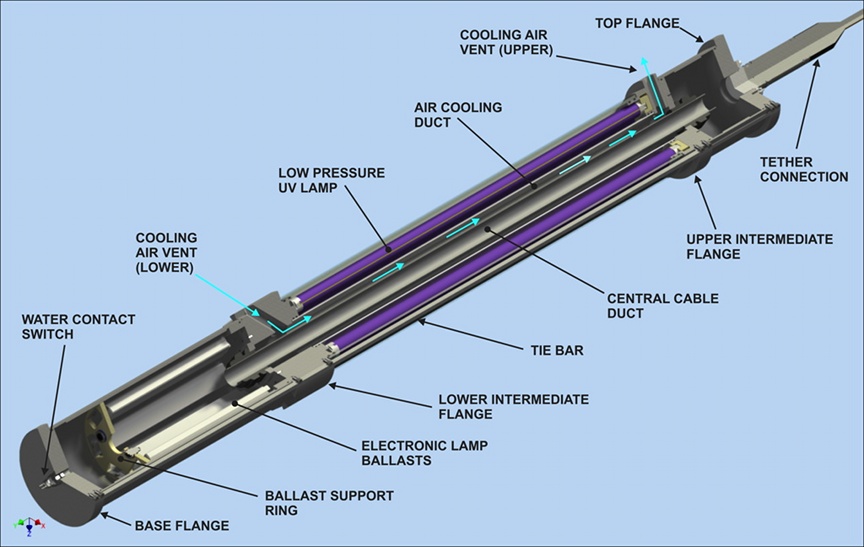

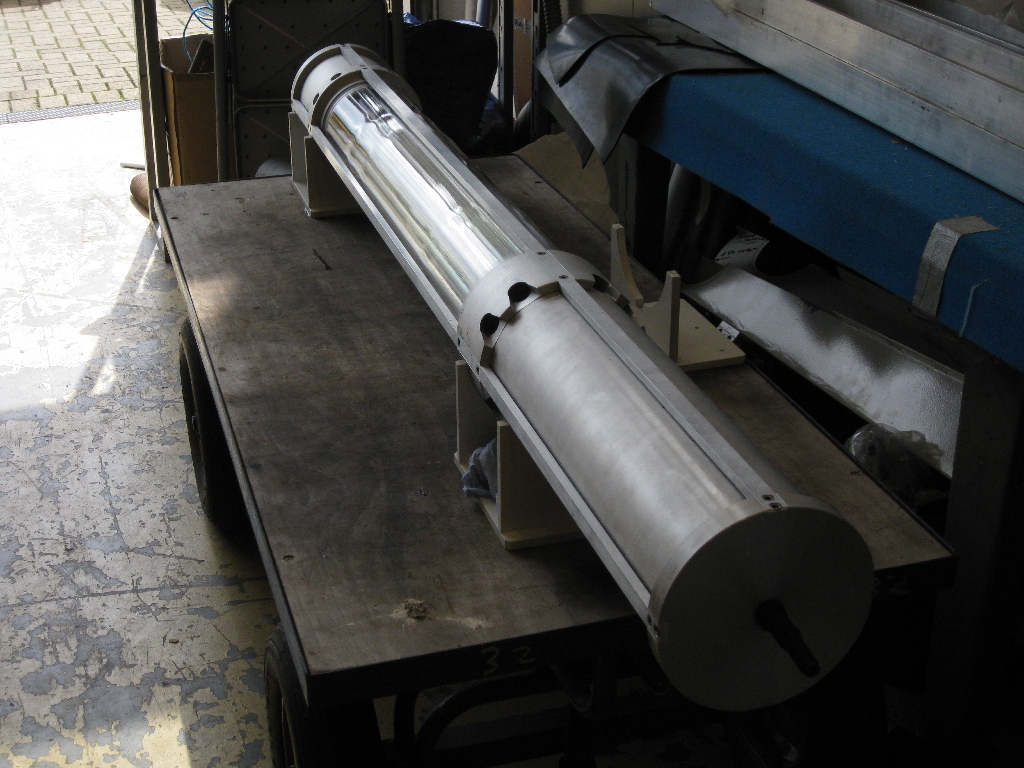

Keen Marine was commissioned to design and deliver a couple of pieces of equipment, one of which is an Ultraviolet reactor for disinfecting the upper parts of the borehole through the glacial ice to the hydrostatic pressure head once the lake had been breached, a distance of around 300m. The attempt to reach the lake made in the Austral summer of 2012 was, for various technical reasons, not successful so sadly this equipment never got a chance to be deployed in earnest. It will have to wait until a suitable borehole can be drilled to the lake. The scientific goals remain relevant however and a future campaign will in all probability be mounted sometime in the next few years.

Our paper describing the UV reactor, written in collaboration with Mario Brito at the National Oceanography Centre in Southampton, has been published in a special edition of the Annals of Glaciology focusing on technologies for clean access to subglacial aquatic environments.

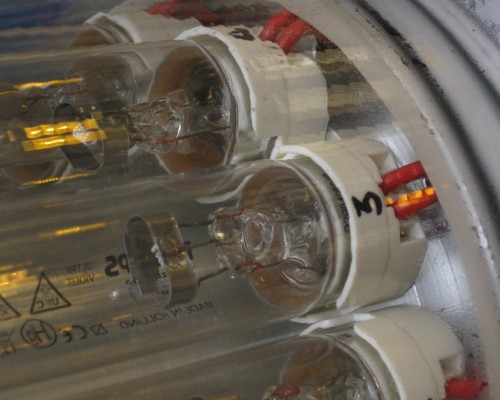

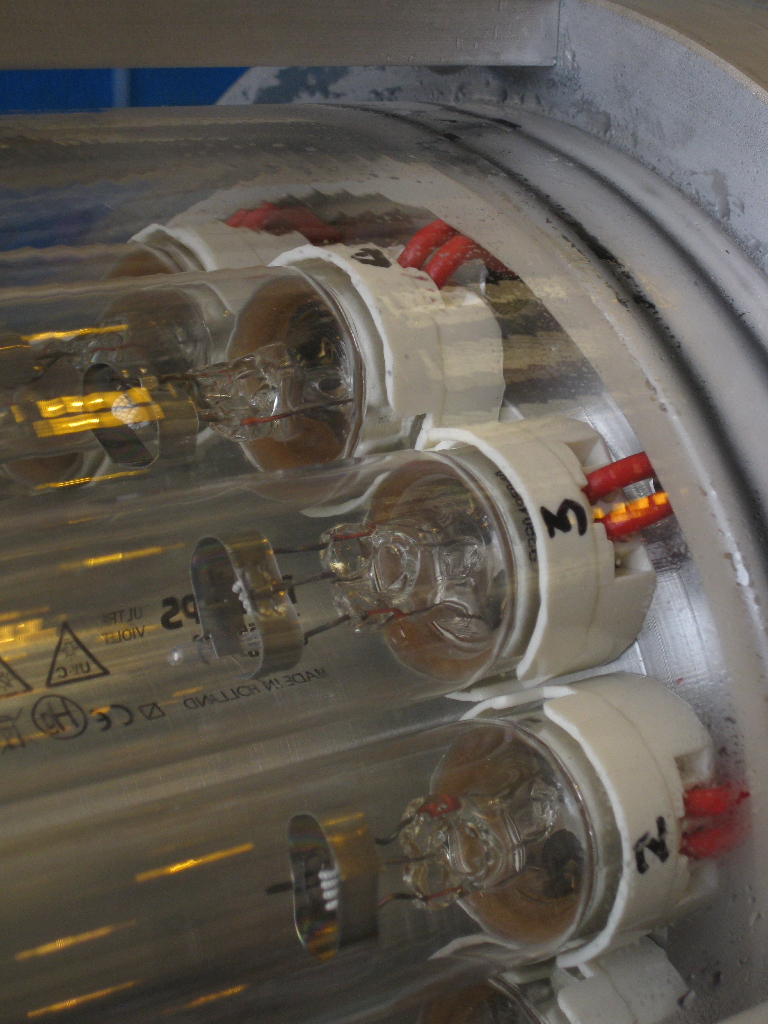

Here is the abstract from the paper and some illustrations of the apparatus.

Design considerations and solutions in rapid-prototyping an ultraviolet reactor for ice borehole disinfection

Peter W. Keen (Keen Marine Limited)

Mario P. Brito (Natural Environment Research Council)

Abstract

Gaining access to subglacial lakes presents major technological challenges. To comply with conventions covering the exploration of pristine Antarctic environments access should be conducted so the lake is not contaminated in any way. Consequently, all equipment to enter the lake must be sterile and the entrance should isolate the lake from the external environment.

Currently, clean access to these environments is achieved using a hot water drilling system (HWD). Differences between the hydraulic pressure head of the lake and the glacial surface results in a section of the borehole being air-filled. It is imperative that this section is disinfected prior to introducing any sampling equipment. This paper describes the design process involved in rapid prototyping an Ultraviolet disinfection reactor for achieving this goal. Considerations such as UV output, physical constraints, temperature management, and deployment procedures are assessed. We present a design that addresses these considerations.

Ж

The full article is published online at the International Glaciology Society’s website: Annals of Glaciology 55(65)

Completed reactor awaiting cool room testing (-20 deg. C)

Completed reactor awaiting cool room testing (-20 deg. C)